Environmental Cover Systems

Environmental Cover Systems

SynTechnics Environmental Cover Systems efficiently and economically capture odors and vapors created by substances contained in tanks or reservoirs. Made of Fiberglass Reinforced Plastic, they provide maximum strength at minimum weight, are aesthetically pleasing, meet demanding environmental requirements and are resistant to corrosion.

These FRP covers also minimize moisture collection points by eliminating excess flanges, fasteners and weldments. They permit use of complex shapes at low costs, minimize maintenance and operating costs and can be assembled on-site.

SynTechnics Environmental Cover Systems provide cost-efficient covering of virtually any size or shape for almost any tank and reservoir.

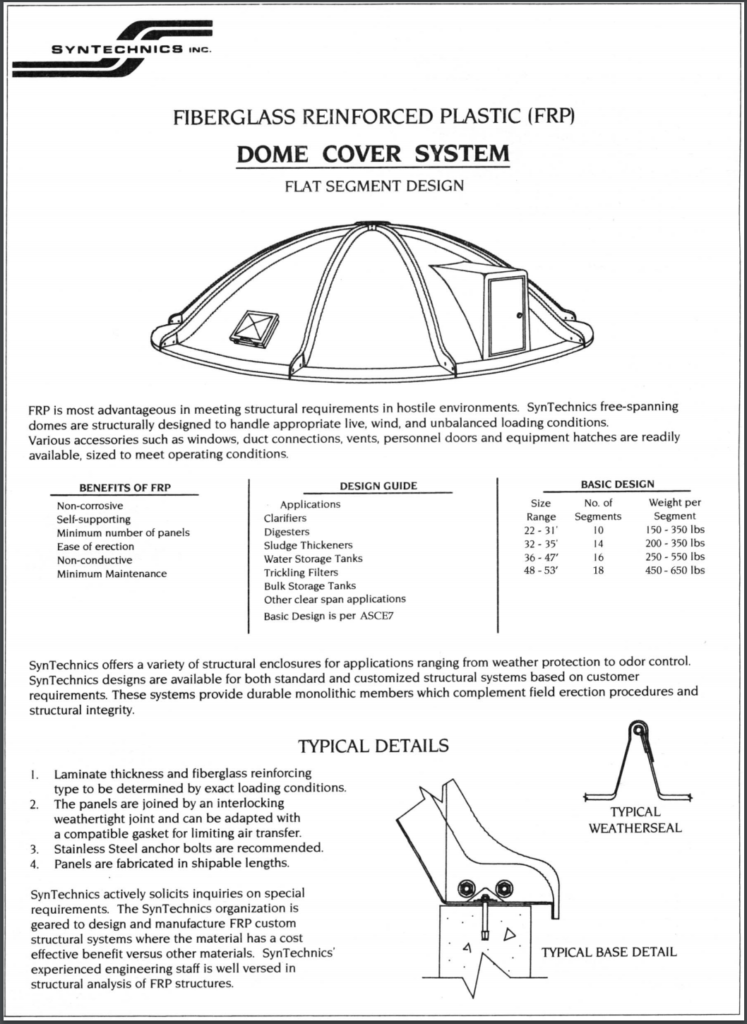

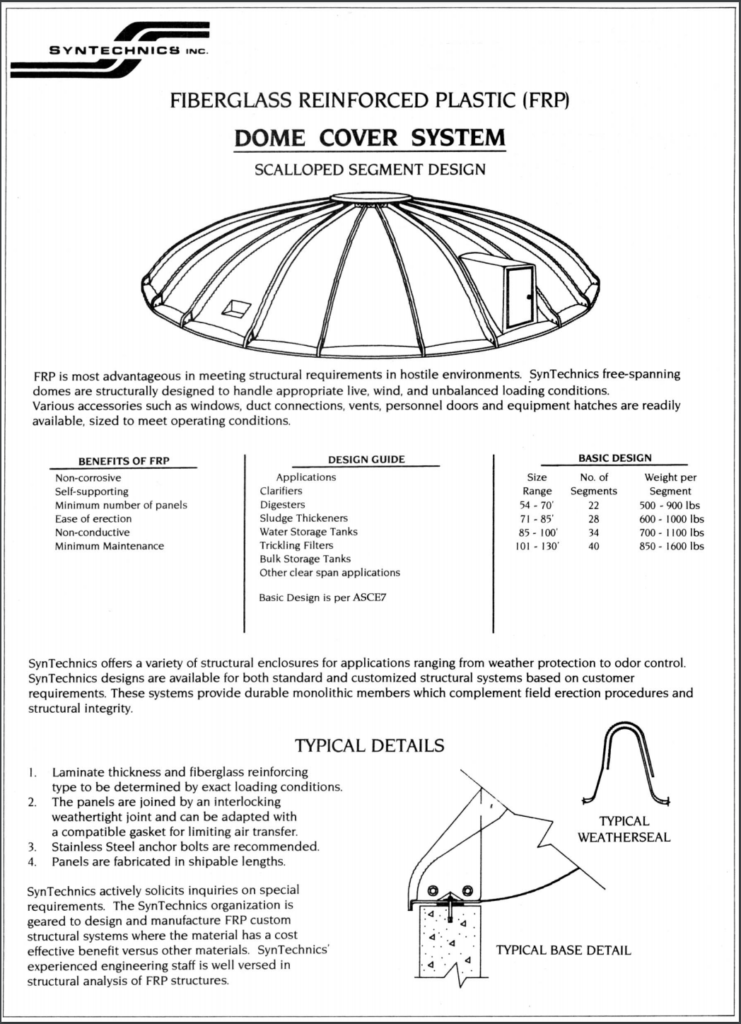

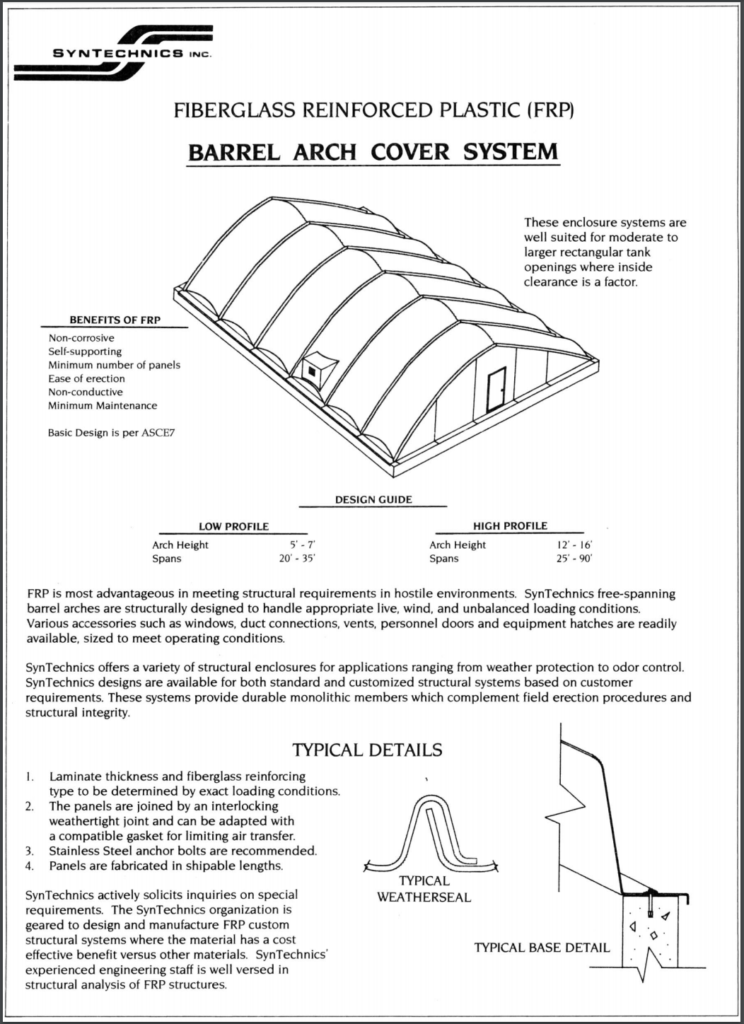

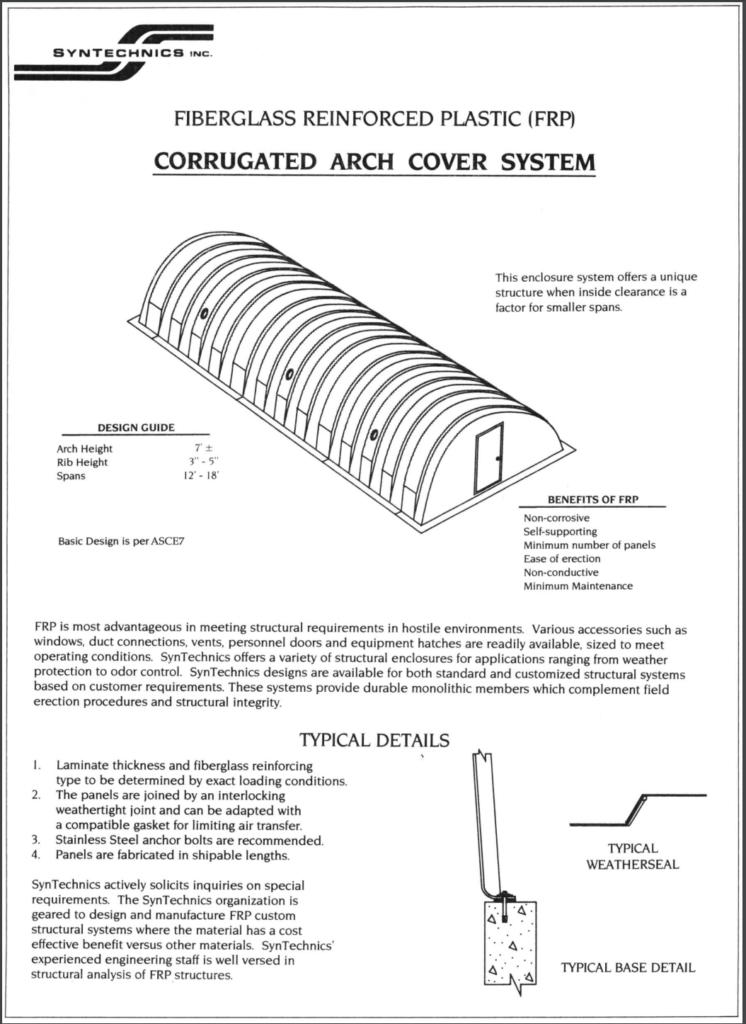

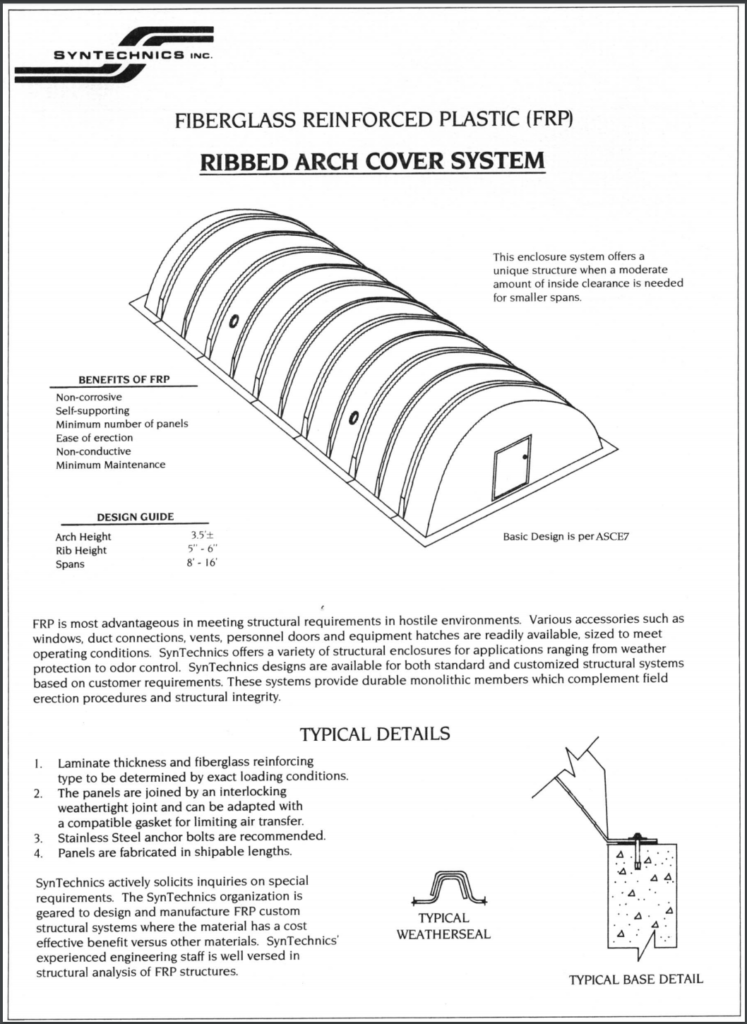

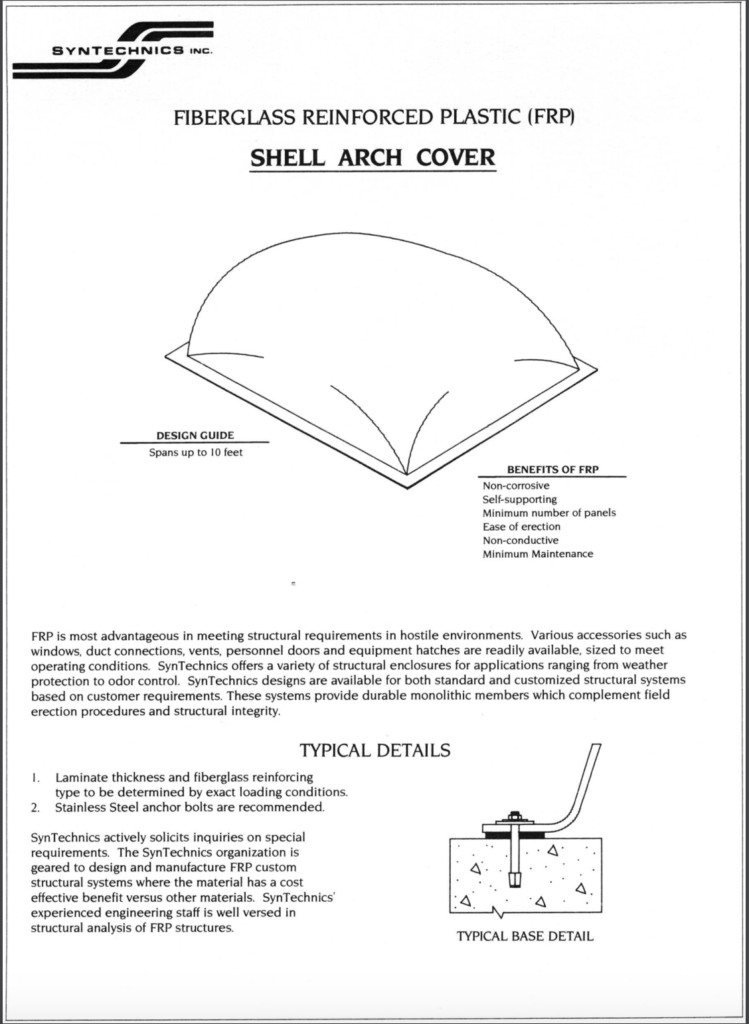

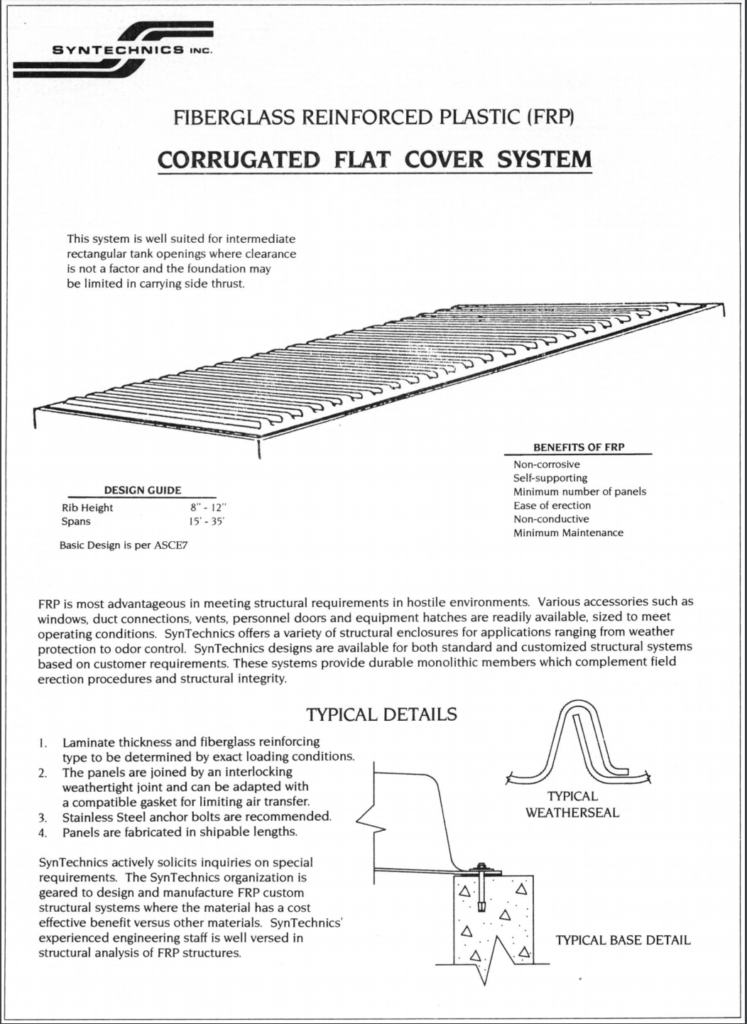

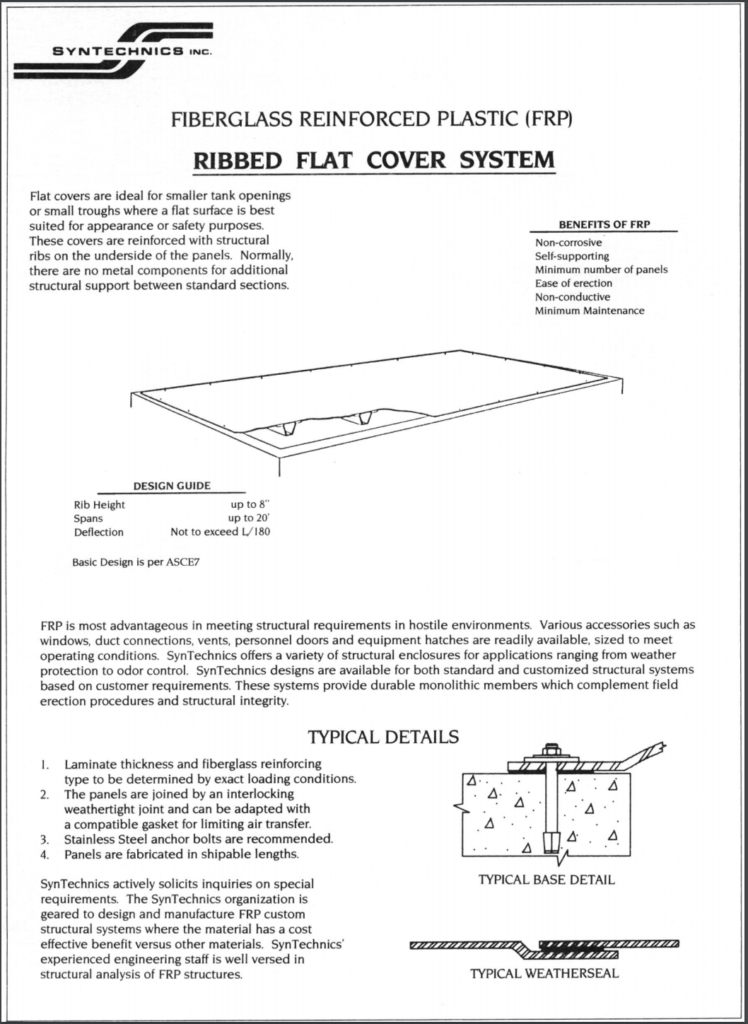

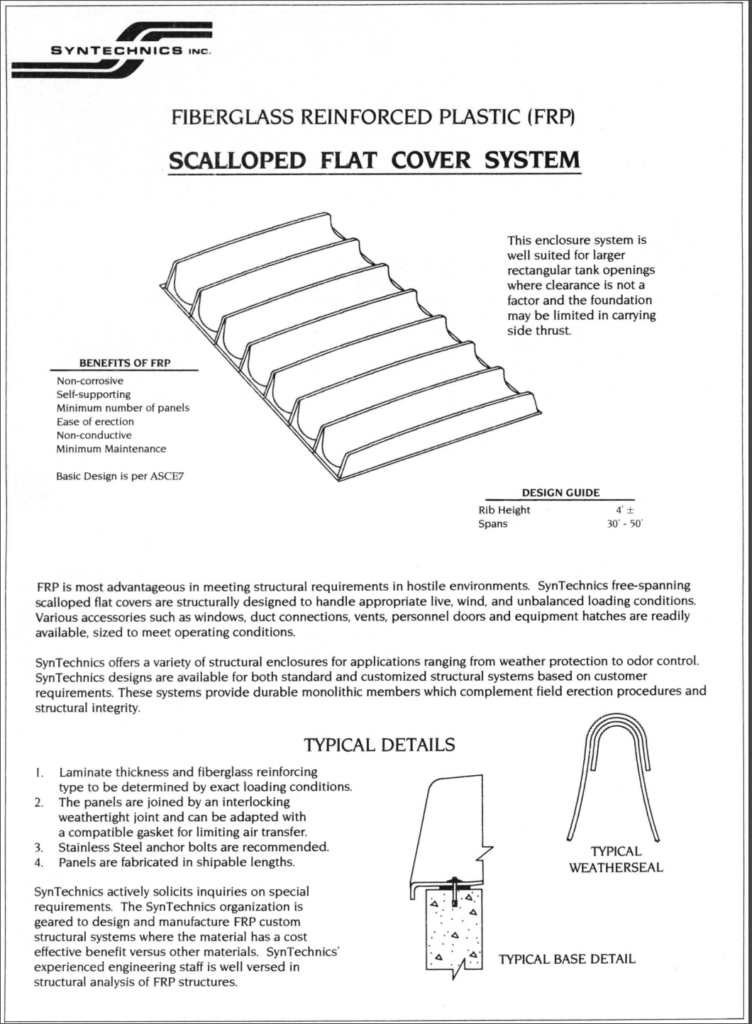

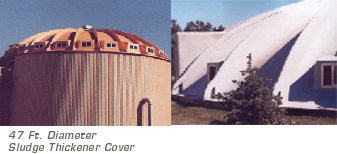

Domes cover circular tanks from 25 to 132 feet in diameter. Arches cover rectangular tanks as large as 90 feet in clear span. Flat covers cover rectangular tanks as large as 45′ in clear span and can be adapted for use on circular tanks as well.

SPECIFICATIONS

Modern female contact molding processes are used to manufacture our environmental cover systems. Cover panels are monolithic molded sections consisting of multiple layers of fiberglass and resin. Each panel is designed to meet or exceed loading requirements. Interior surfaces are coated with a resin-rich finish to provide the proper corrosion resistance. Exterior panel surfaces are protected from outside conditions by a specially formulated gelcoat, which is molded into the primary laminate. The strict manufacturing controls and tested designs make the SynTechnics FRP covering system a leader in the industry.

COVER SYSTEM ACCESSORIES

Available accessories include vent and pipe flanges, access hatches, windows, skylights, manways and full size personnel doors. All are custom designed to meet any customer’s needs.